IDROINOX IMPIANTI SRL - STEEL PLANTS FOR FOOD INDUSTRY

Thanks to the search for excellence Idroinox the plants was the pioneer in the use of steel plants for food industry in the 80s, has achieved ISO already in the 90s and PED since the early 2000s, which allowed achieve autonomy in plants "turnkey".

MISSION

Design, construction and installation of steel plants for food industry, pharmaceutical, cosmetics and electronics operating directly or in partnership with engineering firms and general contractors in Europe for major national and international companies in the sector.

The Idroinox Systems aims to:

-Packages provide "turnkey" solutions of salt preparation for pharmaceutical and food industries, including the commissioning;

-Provide steel plants for food industry and corresponding equipment;

-Packages provide "turnkey" of distribution circuits PW, WFI, PS included the ommissioning;

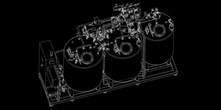

-Provide storage tanks and preparation;

-Provide shell and tube exchangers;

-Provide groups for the production of ozone - Reverse Osmosis - Steam Clean Loop for pharmaceuticals;

-Provide CIP and SIP;

-Provide groups of pretreatment with water filtration, iron and manganese removal, softening and removal pure and ultra pure water according to the USP;

-Prepare protocols and recordings IQ, OQ, and provide documentation necessary for commissioning FDA validation of the system;

-Perform activities Dry, Passivation and Derouging systems "dated" standards-edge.

MAINTENANCE

The decades of experience of Idroinox plants in the construction of steel plants for food industry has encouraged the development of an effective maintenance program.

The company provides this service to all its customers and is active both for the installations of its construction, which for plants built by third parties.

The service includes:

-Inspections in the field;

-Creating lists of materials and spare parts;

-Action planning;

-Replacement of components and spare parts;

-Regeneration plants;

-Activities passivation and derouging;

-Sanitation of plants;

-Acceptance tests and release certification.

POST SALE

The service after sales of Idroinox systems aims to reduce the time of failure or inefficient operation of steel plants for food industry and equipment. In large, modern and efficient automated warehouse, there are some thousands of components ready to be sent to the customer within 24 hours.

The spare parts are run automatically by a software integrated management of bills, codes and automated warehouse.

Indroinox systems ensures timely response to the needs of customers through telephone support, remote control world-wide PLC programs and the availability of emergency response teams for activities of welding and mechanical installation in the field.

WASHING AND PASSIVATION

CORROSION

The steel has excellent anticorrosive properties in contact with most fluids used in the food industry: this is possible thanks to the natural properties of the cover itself with a passivating layer.

However, mechanical processing, such as cutting and welding, which are carried out during the construction of the installations go to create discontinuity in the protective layer of chromium oxide that naturally wrap the material, making the steel plants for food industry most vulnerable to the effects corrosion.

For this you need to submit the steel plants for food industry to wash cycles and passivation.

THE ROUGE

The rouge is a phenomenon well known in the food industry that uses ultra pure water at high temperature. The main constituent of "ROUGE" is given by iron oxides, which form a patina ranging in color from reddish to deep black, which over time gradually coats the inner walls of the steel plants for food industry. Periodically it is necessary to subject plants to cleaning operations so-called "derouging".

WASHING PASSIVATION AND DEROUGING

Idroinox plants has long term experience in the business of cleaning, passivation and derouging.

These activities are carried out with products and tools aimed to steel plants for food industry each of which has been previously tested in hundreds of interventions washing & passivation and derouging at the most reliable pharmaceutical multinationals.

THE CONTROL

A check that passivation is performed with testers and procedures that measure the residual potential corrosion of the pipe. The control process takes place in full respect of the USA FEDERAL REGULATIONS.

Idroinox plants offers a wide range of services commissioning allowing the final customer to obtain considerable advantages in terms of time and costs going to greatly reduce the probability of error in the design phase.

Some of these services are:

-With inspection and auditing of 'installed;

-Calibration;

-Adjusting and setting components;

-Starting plants;

-FAT with the testing official factory;

-SAT with the execution of official tests at the installation site;

-Training of staff;

Idroinox then Impianti Srl is a company specialized in the design, production, installation and maintenance services to steel plants for food industry.